A car isokinetic CV Boot knowledge joints (CVJ) on the presentation:

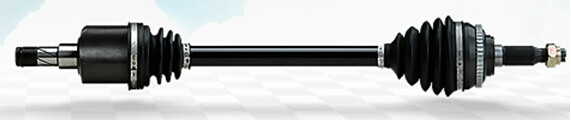

CV Boot automobile constant velocity joint (CVJ) on automotive steering systems Cage shield for storing lubricants and avoid dust, water and salt into the lubrication system. Performance requirements must have excellent (high temperature) fatigue resistance, heat oil long-term erosion. CVJ structure shown in Figure 1:

Figure 1 CVJ Photos

Currently in China, most of the car constant velocity joint (CVJ) dust cover is made of rubber, the use of die-casting, but in Europe, the United States, Japan, South Korea and other car developed 10 years ago on the use of thermoplastic elastomer TPEE plastic instead of rubber CR (chloroprene rubber), and the world TPEE thermoplastic elastomer raw materials, mainly monopolized by the United States DuPont DuPont TPEE and Dutch DSM DSM TPEE, TPEE prices of raw materials are more expensive than other raw materials, about 7 tonne -8 million meal. But the world of auto parts development, must be TPEE thermoplastic elastomer plastic instead of rubber CR (chloroprene rubber), the main reasons for the following areas:

• TPEE excellent low-temperature fatigue resistance, oil resistance up to 100 ℃ long-term erosion of the working temperature range is very wide, it can be used in -70 ~ 200 ℃;

• TPEE offer more advantages. Such as: the use of recyclable, centrifugal expansion rate is low;

• Compared with conventional rubber CR (chloroprene rubber), allows weight reduction of 50% by weight, shorten molding cycle 90% longer life times (up 100-30 Wan Km);

• excellent ozone resistance, weather resistance and anti-aging properties.

In China, due to backward technology and equipment, most cars have been using rubber CR (chloroprene rubber) Cage dust cover, resulting in significant maintenance costs, such as the frequent use of taxis, 8-10 months on average, it is necessary replace one, bad maintenance, a few dollars a rubber Cage dust cover, resulting in a thousand dollars to replace the drive shaft, and replacement works great. As with TPEE Cage dust cover, available 5--8 years, and recyclable, in line with the policy of energy conservation and environmental protection vigorously pursued.

Currently, only foreign equipment German company producing secondary species, because the price is expensive, so basically only 5-8 with foreign companies, a limited number of products in China, such as in China, Germany's ContiTech, Korea Photonics Germany, Japan NOK, Toyoda Gosei and so on! Annual production car in the world is China's largest, most are still using rubber-producing rubber dust cover. To keep up with international technological advances, the development of China's independent intellectual property rights machinery, Shunde, Foshan, Guangdong Yung Gui Jinming Plastics Machinery Factory has been dedicated TPEE CV Boot research study. The factory was founded in 1999, located in the "Chinese brand name town" title Shunde High-tech Development Zone, is a specialized production of high-end fully hydraulic blow molding machine business. Given the many domestic auto parts manufacturers to visit our company, we are required integration of the world's most advanced technology, independent research and development, test successfully developed a car TPEE CV Boot Note blowing one blow molding machine, plastic machinery industry in China, Jin Ming is only one company successfully developed.

Figure 2 company developed TPEE CV Boot injection blow one machine

Two: Automotive TPEE CV Boot injection blow molding machine key technologies;

(1) key elements:

Uses and traditional completely opposite tube pulled from the bottom of the feed process, to ensure that each tube length precise size and shape of the curve to achieve set point thickness and shape of the product CV Boot correspondence; in addressing product size and on the basis of shape tolerances, and in order to form a number of small internal thread inside the mouth, through the use of a unique molding method, two sets of molds at the same time, a set of plastic injection mold, a blow molding, injection mold products to achieve internal thread forming a small mouth, blowing molds to achieve a very very steep peaks and valleys gap while maintaining uniform thickness;

(2) key technologies:

CV Boot resolve differences between two caliber and more peaks in the middle to keep the problem of uniform thickness under circumstances very steep valleys are enormous; injection mold products to achieve a small port with internal thread forming; blow mold peaks and valleys to achieve a very big drop Steep keeping under uniform thickness, to ensure that the wall thickness of CV Boot crest and trough of the same cross section is not more than 0.2mm, the thickness of non-peak and troughs in the same section is not more than 0.25mm; control system to ensure completed within 28 seconds the product is formed, takeout, automatic cutting flash, automatic weighing automated process.

Customer For more detailed information, please contact us:

Shunde District of Foshan City, Yung Plastic Machinery Factory

Address: Shunde District of Foshan City, North High-tech Zone (Ronggui) Huatian all the way No. 22

Tel: 0757-28877036

Contact: Mr. xing

E-mail: sdxingjh@126.com

NEWS

NEWS  Company News

Company News